Graphite electrodes are crucial components of modern manufacturing and industrial processes. Without them, many of the processes we rely on today would be impossible. But, how do you get the most out of your graphite electrodes?

In this blog post, we’ll be exploring the most effective ways to keep your graphite electrodes lasting longer and get the most out of your investment. By the end of this post, you should have a good understanding of how to extend the lifespan of your graphite electrodes.

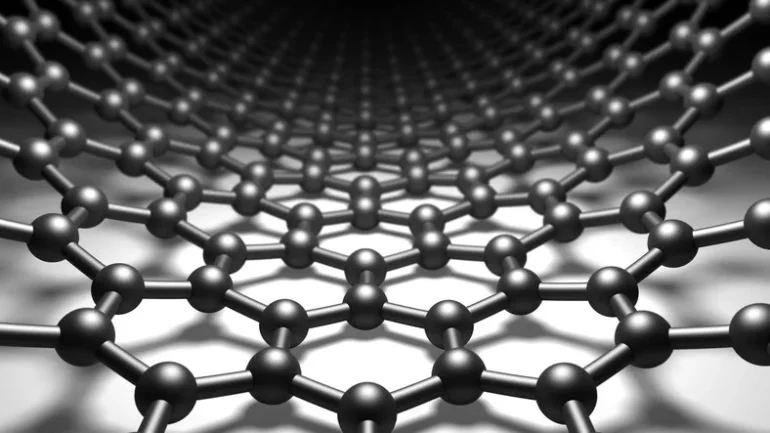

What Are Graphite Electrodes?

There’s nothing like the feel of a well-made keyboard. The keys are soft to the touch, and they’re responsive – you can type fast and accurately without any problems. That’s thanks in part to the graphite electrodes that make up each key. Graphite electrodes are essentially small pieces of metal that act as a conductor for electricity. They’re responsible for transmitting the electrical signals from your computer keyboard to your fingers, which is why they’re so important.

Graphite electrodes offer several benefits that make them a preferred choice for use in high-temperature industrial processes. Here are some of their key benefits:

High thermal conductivity

Graphite has a high thermal conductivity, which makes it an ideal material for use in electric arc furnaces and other processes that involve high temperatures. This property allows the electrodes to efficiently transfer heat to the materials being processed, resulting in faster melting and better-quality products.

Chemical resistance

Graphite is highly resistant to chemical reactions and corrosion, making it an excellent choice for use in harsh industrial environments. Graphite electrodes are often used in processes that involve acidic or alkaline solutions, as well as in the production of metals and other chemicals.

Electrical conductivity

Graphite is an excellent conductor of electricity, which makes it ideal for use in electrochemical processes and other applications that require a high degree of electrical conductivity.

Mechanical strength

They are also known for their high mechanical strength, stiffness, and wear resistance. This makes them suitable for use in a wide range of mechanical applications, including bearings and seals.

Cost-effective

They are often more cost-effective than other materials, such as copper or silver, while still providing high performance and durability.

Unfortunately, they don’t last forever. Over time, they can become worn down and lose their ability to transmit electric signals effectively. This can lead to typographical errors and other issues with your keyboard operation. Fortunately, there are ways to extend the lifespan of your graphite electrodes – by properly caring for them, of course! Here are some tips on how to do just that:

- First things first – make sure that you have an accurate understanding of what a graphite electrode is and how it works. Once you know this information, you’ll be able to take proper care of your equipment and avoid issues down the road.

- Next up is storage – keep your graphite electrodes safe by storing them in a cool, dry location away from direct sunlight or heat sources. Make sure that they’re accessible when you need them but out of reach of children or pets – accidents happen!

- In terms of usage – there are many applications where graphite electrodes can be beneficial! They include gaming keyboards, scientific instruments such as spectroscopes or microscopes, and even electric vehicles! When choosing an application for use with graphite electrodes, it’s important to consider both the advantages and disadvantages compared with other conductive materials like copper or carbon nanotubes.

Common Causes Of Damage

Graphite electrodes are essential for a variety of welding applications, and proper handling is essential to ensuring their longevity. If you’re not familiar with graphite electrodes, they are a type of electrode that is used in arc welding. They have many benefits over traditional metal electrodes, including the ability to hold a higher current and resist heat damage.

The first step in preventing electrode damage is identifying the common causes. This includes understanding how improper handling or storage can lead to damage. For example, if you store them in an environment where they are exposed to moisture or extreme temperatures, it can cause them to become damaged. Additionally, hot spots on the electrode can be easily damaged due to contact with other objects or bodies of water.

To prevent these types of problems from occurring, it is important to preheat and post-heat them before and after welding. This will help reduce the risk of accidental contact and damage. Additionally, it’s important to use caution when welding near water – always make sure that there’s plenty of room between your welds and any bodies of water. Finally, proper maintenance is essential for keeping graphite electrodes in good condition – regular cleaning and inspection will help ensure that they last longer than expected.

Tips To Reduce Wear And Tear On Graphite Electrodes

Graphite electrodes are an important part of the electrochemical cells that make up most batteries. They’re responsible for transferring electrons between the battery and the external environment, and as such, they need to be treated with care. By following a few simple tips and keeping them in good condition, you can prolong their lifespan and reduce wear and tear on the metal parts.

One of the first signs that your electrodes are starting to wear down is if there is any wear or tear on the graphite particles. This can be determined by taking pictures of the electrode before and after a discharge cycle (discharge = charging). If there is significant wear, it will show up as black spots on the photo of the electrode after discharge.

It’s important to ensure that all procedures for electrode maintenance are followed closely in order to avoid any damage. For example, make sure that you’re using a protective coating on all metal parts of your graphite electrodes to prevent corrosion. Make sure that you’re using working temperatures within the recommended range set by your manufacturer, and keep an eye out for signs of overheating such as excessive heat generation or discoloration of insulation material around the cells.

Most importantly, make sure you have quality graphite electrodes by investing in a high-quality product from a reputable supplier. Follow a strict maintenance schedule – this will help to keep them in good condition while they’re working hard!

To Conclude

Graphite electrodes are an essential component of modern manufacturing and industrial processes, but they can become worn down and damaged over time. This blog post has provided a comprehensive guide to extending the lifespan of your graphite electrodes, from understanding what they are to common causes of damage and tips for storage and usage.

With careful maintenance and proper handling, you can ensure that your graphite electrodes last longer and continue providing reliable performance for years to come. Take the necessary steps today to maintain the longevity of your graphite electrodes – you won’t regret it!