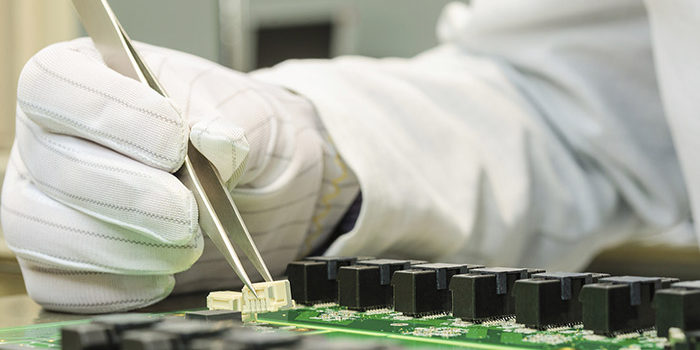

There is a growing demand for electronic components and the service of their production is widely used. Therefore, it is necessary to constantly work on the development of technical solutions, expertise, and gaining experience in order to meet the growing demands of customers. There is simply a huge need for the most innovative technological advances, and that means encouraging competitiveness with different manufacturers. However, that is why we are working on improving operational efficiency and increasing activities in the areas of research and overall development.

Keep in mind that the market is overlooked dynamically and standards are just continuing to rise. Although you are constantly facing challenges, it is necessary to understand the driving factors and take them into account when planning. If you want to learn more about it and take advantage of all the current opportunities, keep reading. Below we will present you the most important tips for outsourcing electronics manufacturing.

1. Defining requirements

Different manufacturers have different goals. So, you need to understand exactly what you want. For example, you may need a larger capacity partner or an entire production facility for certain purposes. Or maybe you need customer service and this website can give you more answers on that. Either way, your list must include priorities.

Some things just have to be separated. It is crucial to distinguish between those goals that must be achieved as soon as possible and those that would be good to achieve. You also think about the consequences of certain decisions, because if you decide on a partner with a larger capacity, you may have to work with him at a distance or something similar. This means that you have to organize yourself on several sides at once, and then you need strong business practice and flexibility.

2. Search

When you start defining the requirements, you decide on a long selection process. So the most important thing is to try to anticipate some complexities, and you will succeed if you apply responsiveness and flexibility. Your list of goals can be well conceived if you check some tangible areas first. This approach will definitely help you determine if some things are compatible or just not. In that case, starting the search on time is vital. However, it is not enough just to do this, but in addition, you have to and constantly update it if certain changes occur.

Most professionals do this work by doing a search while at the same time being guided by recommendations. This approach has proven to be the most effective way to work because it leads to a narrowing of choices so quickly. When you get to the details of the investigation, you will already drastically reduce the choice and thus close the deal very quickly.

3. Partners

After preparation and long research, you start digging really deep here. So, everything that precedes the selection of a potential partner should be completed in one moment and you should move on to a specific job. When you have narrowed down your choices, it is important to schedule individual meetings to discuss some details. Then you should tell them everything about yourself as well as your products. Of course, you must not omit the goals and ask them a few basic questions accordingly. You need to construct them so that you find out if any of them offer what you need, and that is certainly adapting to your requirements.

Based on the answers, you will easily determine this and after that, you can visit their location. The company you physically visit will make the final verdict and decide. We are telling you this for a few simple reasons. The feeling that this kind of experience offers you is priceless because then you will really get to know it completely. By that, we mean its culture, people, and all the possibilities that were mentioned earlier. You will often be convinced of that or your feeling will prove just the opposite, but something like this is absolutely necessary.

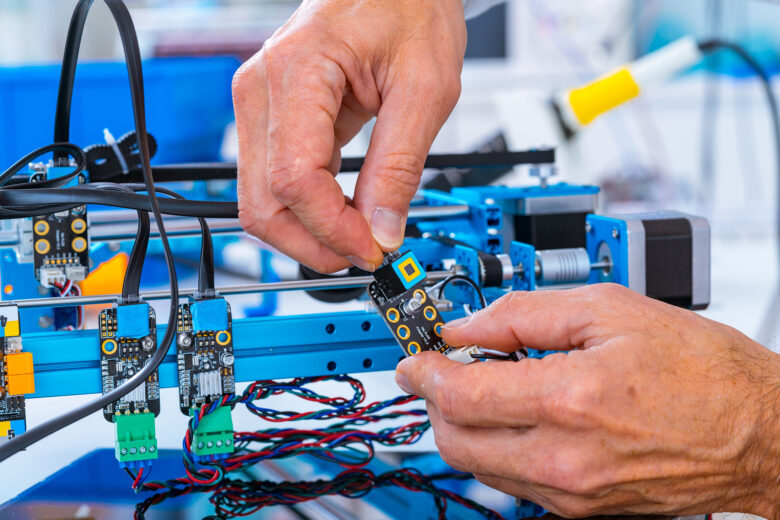

4. Technicality

You need to make another assessment, and that refers to the annual quantities of all the products you need. By that we mean some common things like orders, batch size, etc. Of course, if you use blueprints it is important to count on additional costs. So, it is important to think about absolutely every detail and to organize yourself on several sides, because that will be expected of you. While you may be submitting really a lot of data, don’t think that’s the end of it because there can always be certain changes or unexpected issues. If you do good research and prepare in the right way, you will have the answer to everything.

You also need to pay attention to all the important people in this process, and that applies to those who oversee the production, such as managers in various fields. Ask them how they look at the whole business or what their thoughts and ideas are. It is important that they give you an insight into their ideas when it comes to the elements of production and management. You must be perfectly informed. Inquire about processes and procedures. This refers to some common questions regarding the type of control represented, risk and change management, recycling, etc.

5. Outbound logistics

Logistics is an equally important aspect. When we say this, we mean specifically its simplest form, and that is storage, transport, and distribution of products. It usually consults with a partner before production is approved. And they arrive in personal packaging. However, this allows a preview to be performed before it is sent. On the other hand, the level of logistics costs needs to be properly maintained. You will do this by clearly distinguishing what is not necessary for you and it adds time and costs to you.

Conclusion

If you follow some of our tips, we are sure that you will use the maximum potential in this industry. Then you will be able to use engineering resources properly and you will be maximally focused on priorities. You will also have more self-confidence when it comes to overall business functioning and thus achieves a unique approach to skills and other resources. In the end, once you know what you’re doing, it’s much easier to eliminate overhead, increase expertise for prototyping, and overall design.